Nano Res.│武汉理工大学谢毅教授:具有梯度和多级结构的高耐候超双疏防污闪涂层材料

背景介绍

室温硫化硅橡胶(RTV)已被广泛应用于高压绝缘子防污闪,然而RTV表面的疏水特性易遭受破坏,当RTV表面上形成水滴,会导致气-液-固边界处的电场增强,电晕放电导致疏水性降低。疏水性的减弱会降低绝缘表面抑制漏电流和局部放电的能力,从而容易发生闪络事故。近年来,超疏水(SH)材料被认为是传统RTV的一种最有前途的替代材料,可有效提高绝缘子的防污闪性能。在绝缘子表面涂覆超疏水材料,由于其具有超强的拒水能力,可有效防止水粘附在器件表面,赋予绝缘子表面较大的漏电距离,抑制泄露电流,降低闪络的可能性。然而考虑到材料在实际使用过程中,自然界存在的一些污秽物如鸟粪等含有有机污染物。这些有机物容易附着在超疏水绝缘子表面,从而导致可溶性盐类和水的集聚,削弱其污闪性能。

鉴于此,武汉理工大学与伦敦大学学院、华中科技大学等合作,提出了一种具有独特梯度结构的耐久性超疏水超疏油(超双疏)涂层的制备方法并应用于电力设备防污闪领域,由于其优异的拒水拒油性能,在实际使用过程中涂层不会受到自然界中有机污秽物的影响,从而有效提高了高压输电线路绝缘子的防污闪性能。

研究方法

本研究超双疏材料的制备采用喷涂“底漆+面漆”的工艺,通过控制喷涂压力、喷涂距离等获得具有独特梯度结构的超双疏(SAP)涂层。材料的表面形貌、微观结构、表面结构、化学成分等采用SEM、TEM、EDS、FTIR等进行测试分析。采用砂纸打磨的方法测试材料的耐磨性,采用紫外光照、酸碱液浸泡、低温冷冻及高温退火等方法对材料的耐紫外稳定性、耐化学稳定性及耐高温低温稳定性。各种涂层绝缘子(如超疏水、超双疏及RTV 涂层玻璃绝缘子)的污闪试验是在人工污闪试验台上进行,在施加电压之前,绝缘子表面采用人工污秽物(硅藻土和NaCl的混合物)进行污染,并在加湿器的雾室中完全暴露于饱和水蒸汽中15分钟后取出置于污闪试验台进行试验;通过逐渐升压直到发生闪络,并记录闪络电压值。

成果简介

(1)发展了一种具有独特梯度结构的超双疏材料设计及其构筑方法,该梯度结构的构筑有效提高了超双疏涂层材料的耐磨性能。

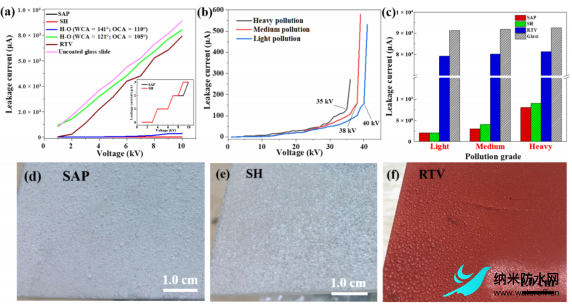

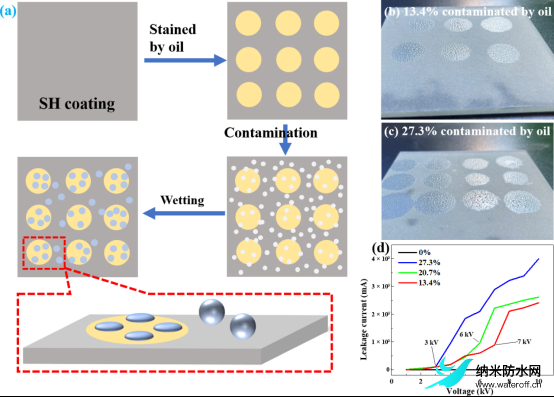

(2)提出了一种新的污闪性能评估模型,该模型考虑了有机物污染对设备防污闪性能的影响,并通过绝缘子污闪试验进行了验证。研究表明,当超疏水绝缘子表面被有机物污染后,其污闪电压降低,即防污闪性能下降。而超双疏绝缘子在相同条件下污闪性能基本不受影响。

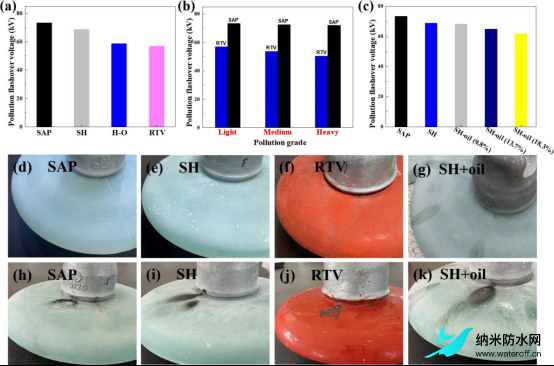

(3)发展了一种采用超双疏涂层材料提高输电线路用绝缘子的污闪性能的方法,其防污闪性能远优于传统RTV。在轻度和重度污染等级下,创制的超双疏绝缘子的污闪电压比传统RTV绝缘子在相同条件下分别提高了29.0% 和42.9%。

图文导读

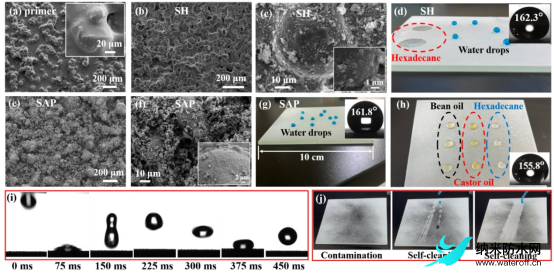

Figure 1 (a) SEM images of the primer showing mastoid morphologies of the surface. (b) and (c) SEM images of the SH coating displaying hierarchical micro-nanostructure of the surface. (d) The surface superhydrophobicity of SH coating enables the spherical water droplets (dyed with methyl blue) resident on top, while oil drops completely spread on the surface. (e) and (f) SEM images of the SAP coating surface showing hierarchical micro-nanostructure. (g) and (h) The superoleophobicity and superhydrophobicity of the SAP coating enable the spherical dyed water droplets and organic droplets (e.g., bean oil, hexadecane, and castor oil) resident on top. Insets in panels ((a), (c), and (f)) provide the high-magnification SEM images of the corresponding surface. Insets in panels ((d) and (g)) provide the optical images of the resident water droplets on the corresponding coating when measuring WCA. Inset in panel (h) reports the optical image of the hexadecane droplets on the corresponding coating when measuring OCA. (i) Water droplet (5 μL in volume) pinning and re-bouncing behaviour when released from a height of 2.5 mm toward the SAP surface. (j) Dropping dyed water on the fly-ash-contaminated SAP coating to display the self-cleaning performance of the SAP surface.

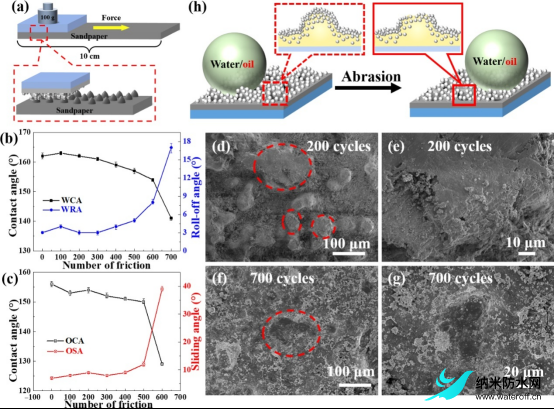

Figure 2 (a) The scheme illustrating the sandpaper abrasion test. (b) and (c) Evolution of WCA and WRA (b), and OCA and OSA (c) on the SAP coatings over sandpaper abrasion cycles. The oil for OCA and OSA tests is pump oil. (d)–(g) SEM images of SAP coatings after sandpaper abrasion test for 200 cycles ((d) and (e)), and 700 cycles ((f) and (g)), respectively. (h) The mechanism on persistence of superamphiphobicity upon sandpaper abrasion.

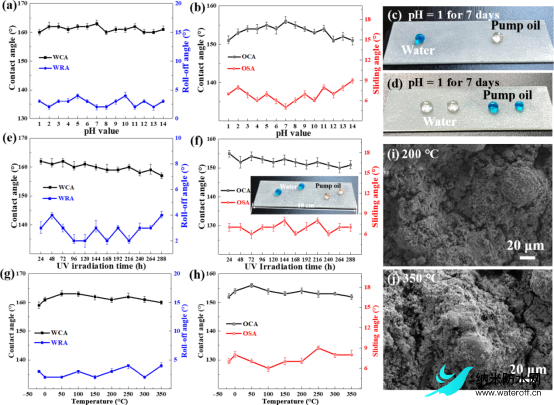

Figure 3 Chemical stability ((a)–(d)), UV irradiation stability ((e) and (f)), and thermal stability ((g)–(j)) of the SAP coating. (a) and (b) The evolution of WCA, and WRA (a) and OCA, and OSA (b) of the coated SAP glass slides after having been soaked in solutions of different pH values for 168 h. (c) and (d) Digital photographs displaying that both water and pump oil droplets preserve sphere-like shape on the coatings collected after submersion in extreme corrosion solutions (e.g., pH = 1 and pH = 14 solutions, respectively) for 168 h. (e) and (f) The evolution of WCA, and WRA (e) and OCA, and OSA (f) of the coated SAP glass slides over UV irradiation time. Inset in panel (f) shows the digital photograph of the coating together with water and pump oil droplets after 288 h of UV irradiation. (g) and (h) WCA, and WRA (g) and OCA, and OSA (h) of SAP coating treated at different temperatures for 2 h. (i) and (j) SEM images of the SAP coatings treated at 200 and 350 °C, respectively, for 2 h.

Figure 4 (a) Experimental measurement curves of leakage current and DC voltage of the various coatings under light pollution environment. Inset provides the enlarge view of the curve regarding SAP and SH coatings. (b) Experimental measurement curves of leakage current and DC voltage of the SAP coating under three levels, namely heavy, medium, and light contamination. (c) The column chart of leakage currents of various specimens as dictated under 10 kV of DC voltage and heavy, medium, and light pollution environment, respectively. (d)–(f) Digital photographs of SAP (d), SH (e), and RTV (f) coatings after contamination by diatomite powders and wetting in the fog chamber.

作者简介

武汉理工大学谢毅教授团队长期从事能源与环境功能纳米材料领域的研究工作,主要致力于半导体纳米晶和纳米结构合成及其化学转换、材料表界面修饰及功能薄膜材料(如超浸润薄膜)制备、基于表面等离子体共振的光热转换材料(金属硫族化合物、MXene等)制备及其上述材料在新能源、发光、光催化、自清洁、电力防污闪、防冰除冰、海水淡化等领域的应用研究,并取得了一系列标志性成果。研究成果发表于J. Am. Chem. Soc., ACS Nano, Chem. Mater., Nano Res., ACS Appl. Mater. Interfaces, Nanoscale, J. Colloid. Interf. Sci.等国内外重要学术刊物上。

随着电子产品防水需求的不断提高,从原先的 IP54到现在的IP67IP68等级!市场上出现了防水透气膜和防水透音膜,目前这两种不同的材料应用被搞混了,今天便与大家一起讨论防水透气

最近各地降雨量激增,所以手机就难免会沾点水,作为生活中不可或缺的电子产品,防水已经成为一个十分重要重要功能,而且个人对目前的IP68手机市场是相当不满意的。为什么?太贵

自然界中荷叶具有出淤泥而不染的典型不沾水特性(学术上称为Cassie-Baxter状态),具有自清洁、抗结冰、减阻、抗腐蚀等广泛应用价值,而玫瑰花瓣则具有水滴高粘附特性(称为Wenze

派瑞林各种粉材真空镀膜技术加工 纳米涂层防水处理

派瑞林各种粉材真空镀膜技术加工 纳米涂层防水处理

高阻隔强绝缘防汗液涂层蓝牙耳机3C电子产品IPX7纳米材料

高阻隔强绝缘防汗液涂层蓝牙耳机3C电子产品IPX7纳米材料

耐磨超疏水纳米材料 绝缘子架空导线电缆桥梁防覆冰涂层

耐磨超疏水纳米材料 绝缘子架空导线电缆桥梁防覆冰涂层

真空等离子气相沉积技术纳米防水镀膜加工 产能5万片天

真空等离子气相沉积技术纳米防水镀膜加工 产能5万片天

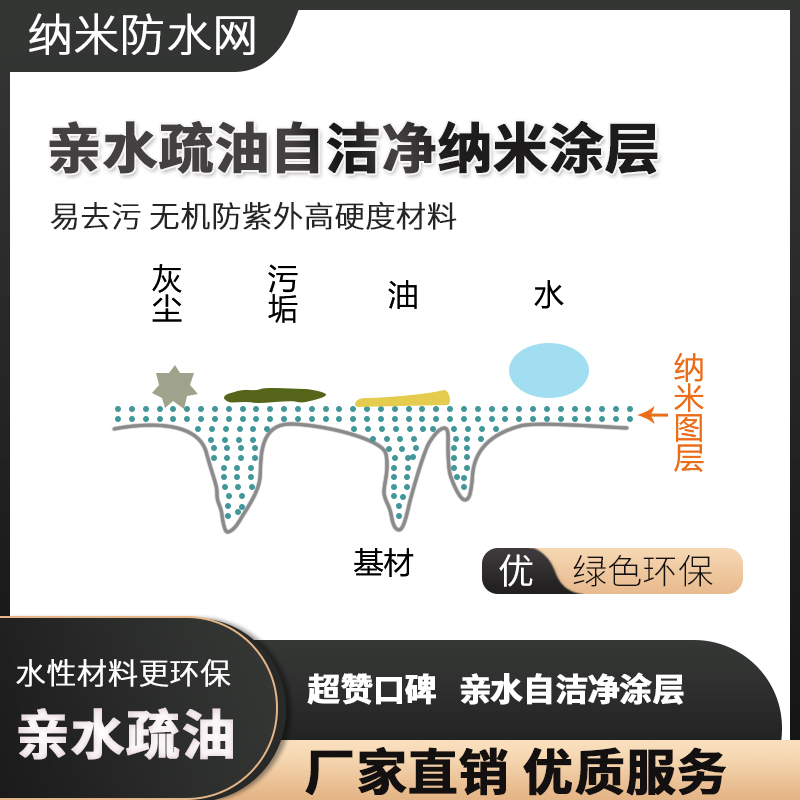

亲水疏油自洁净纳米涂层 易去污 无机防紫外高硬度材料

亲水疏油自洁净纳米涂层 易去污 无机防紫外高硬度材料

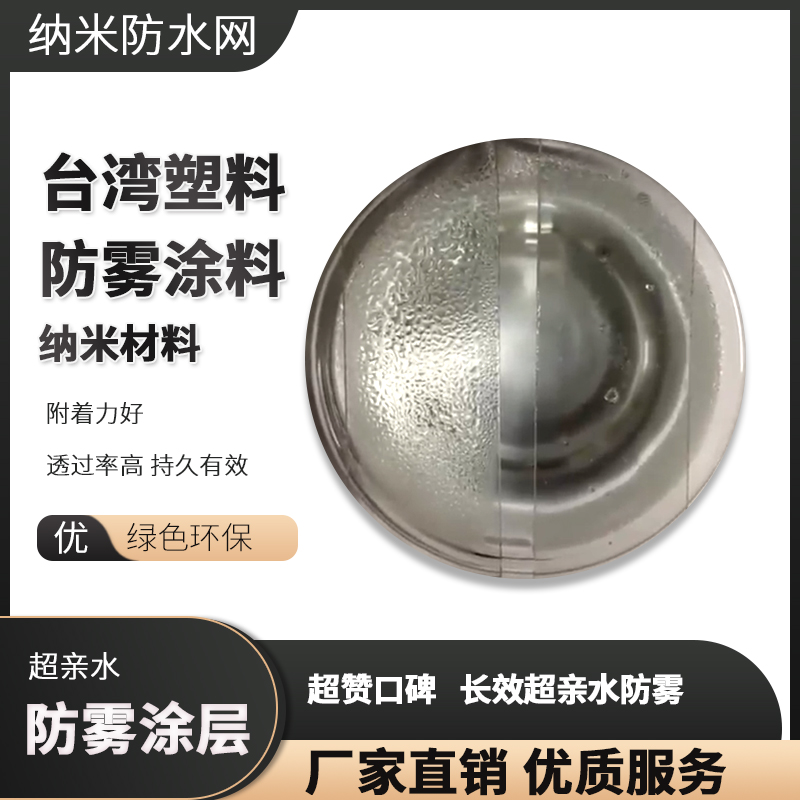

台湾超亲水防雾塑料专用 附着力好 透过率高 持久有效

台湾超亲水防雾塑料专用 附着力好 透过率高 持久有效