派瑞林涂层用于橡胶产品的讨论

Para-Coat Technologies Parylene保形涂层服务提供解决方案,并为弹性体零件提供保护,包括电子,医疗,航空航天,汽车和军事应用。聚对二甲苯涂层可保护各种橡胶和弹性体组件,包括垫圈和密封件,键盘和医用导管。医用级硅树脂或橡胶产品受益于Parylene涂层提供的生物相容性,无毒和化学惰性保护屏障。

Parylene涂层通过气相沉积工艺在真空室中施加,并且在涂覆过程中,聚对二甲苯单体能够渗透橡胶和塑料的表面,从而提供优异的粘附性。Parylene薄而透明的柔韧特性通过保护表面和改善表面特性,提高了橡胶和弹性体组件的性能。在不降低部件功能性能的情况下进行这些改进。Parylene产生真正的保形涂层部件,在平坦的表面区域和孔的内部尺寸周围具有一致的厚度。无针孔聚对二甲苯涂层可以防止物质转移到涂层基材中或从涂层基材中转移出来,即使在一个或两个微米层中也是如此。Parylene保形涂料密封微孔隙并封装最复杂的印刷品,

Parylene的干膜润滑性

固有的优异干润滑特性,其系数摩擦系数接近PTFE的应用范围,使得聚对二甲苯作为干膜润滑剂,特别是作为手术器械涂层的宝贵资产。聚对二甲苯的阻隔性能和化学惰性特别适用于生物医学物体或具有橡胶密封件,柱塞或隔膜的一次性医疗仪器。这种底物可能与人体组织暂时或长时间接触,否则会受到损害。

Parylene的屏障和弹性

Parylene涂层也用于硅橡胶键盘,防止印刷图案,抵抗表面磨损,解决粘性问题,同时保护键盘免受污垢,灰尘和油污。所施加的膜具有高介电强度,并且不损害下面的橡胶组分的电绝缘性能。Parylene提供无针孔,防止潮湿,腐蚀性体液,常见气体,真菌和温度。增加涂层厚度可进一步提高化学耐受性和耐溶剂性,而不会增加重量或实质上影响基板的弹性。

Parylene涂料的优点包括:

· 生物相容性和生物稳定性

· 超薄轻巧

· 微封装功能

· 优异的干膜润滑性

· 卓越的化学,湿气和电气屏障

应用示例包括:

· 医用导管

· 垫圈和密封圈

· 硅橡胶管

· 键盘

· O型圈

· 注射器组件 - 活塞,塞子和塞子

Para-Coat Technologies Parylene conformal coatingservices offer solutions and provide protection to elastomer parts inelectronic, medical, aerospace, automotive and military applications. Parylenecoatings protect a variety of rubber and elastomeric components ranging fromgaskets and seals, to keypads and medical catheters. Medical grade silicone orrubber products benefit from the biocompatible, non-toxic and chemically inertprotective barrier that Parylene coatings provide.

The Parylene coating is applied through a vapordeposition process in a vacuum chamber and during the coating process theParylene monomer is able to penetrate the surface of rubbers and plasticsproviding exceptional adhesion. Parylene’s thin, transparent and flexiblecharacteristics enhance the performance of rubber and elastomer components byprotecting surfaces and modifying surface properties. These improvements aremade without degrading the functional performance of the part. Parylene yieldsa truly conformal coated part with a consistent thickness on the flat surfacearea and around the internal dimensions of holes. Pinhole-free parylene coatingcan prevent the transfer of substances into or out of a coated substrate, evenin one or two micron layers. Parylene conformal coatings seal micro porosityand encapsulate the most complex typographies, providing protection againstpotential leachable ingredients in the elastomer product.

Parylene’s Dry-Film Lubricity

The inherent and excellent dry lubricity characteristics with a coefficient offriction measurements approaching that of PTFE to a range of applications makeParylene a valuable asset as a dry-film lubricant, particularly as a coatingfor surgical instruments. The barrier performance and chemical inertness ofparylene are particularly useful for biomedical objects or single-use medicalinstrumentation items with rubber seals, plungers or diaphragms. Suchsubstrates may come in temporary or prolonged contact with human tissues, andcould otherwise be compromised.

Parylene’s Barrier and Elasticity

Parylene coating is also used for silicone rubber keypads, preventing printedlegends, resisting surface wear, and resolving tackiness issues whileprotecting the keyboard against dirt, dust and oils. The applied film has highdielectric strength, and does not compromise the electrical insulatingproperties of underlying rubber components. Parylene provides a pinhole-freebarrier to protect against moisture, corrosive body fluids, common gasses,fungus and temperature. Increased coating thicknesses further improve chemicaland solvent resistance without adding weight or materially affecting thesubstrate’s elasticity.

Benefits of Parylene Coatings include:

· Biocompatible and biostable

· Ultra-thin and lightweight

· Micro-encapsulation capabilities

· Excellent dry-film lubricity

· Superior chemical, moisture and electrical barrier

Examples of applications include:

· Medical catheters

· Gaskets and seals

· Silicon and rubber tubing

· Keypads

· O-rings

· Syringe components – plungers, plugs, and stoppers

随着电子产品防水需求的不断提高,从原先的 IP54到现在的IP67IP68等级!市场上出现了防水透气膜和防水透音膜,目前这两种不同的材料应用被搞混了,今天便与大家一起讨论防水透气

最近各地降雨量激增,所以手机就难免会沾点水,作为生活中不可或缺的电子产品,防水已经成为一个十分重要重要功能,而且个人对目前的IP68手机市场是相当不满意的。为什么?太贵

自然界中荷叶具有出淤泥而不染的典型不沾水特性(学术上称为Cassie-Baxter状态),具有自清洁、抗结冰、减阻、抗腐蚀等广泛应用价值,而玫瑰花瓣则具有水滴高粘附特性(称为Wenze

派瑞林各种粉材真空镀膜技术加工 纳米涂层防水处理

派瑞林各种粉材真空镀膜技术加工 纳米涂层防水处理

高阻隔强绝缘防汗液涂层蓝牙耳机3C电子产品IPX7纳米材料

高阻隔强绝缘防汗液涂层蓝牙耳机3C电子产品IPX7纳米材料

耐磨超疏水纳米材料 绝缘子架空导线电缆桥梁防覆冰涂层

耐磨超疏水纳米材料 绝缘子架空导线电缆桥梁防覆冰涂层

真空等离子气相沉积技术纳米防水镀膜加工 产能5万片天

真空等离子气相沉积技术纳米防水镀膜加工 产能5万片天

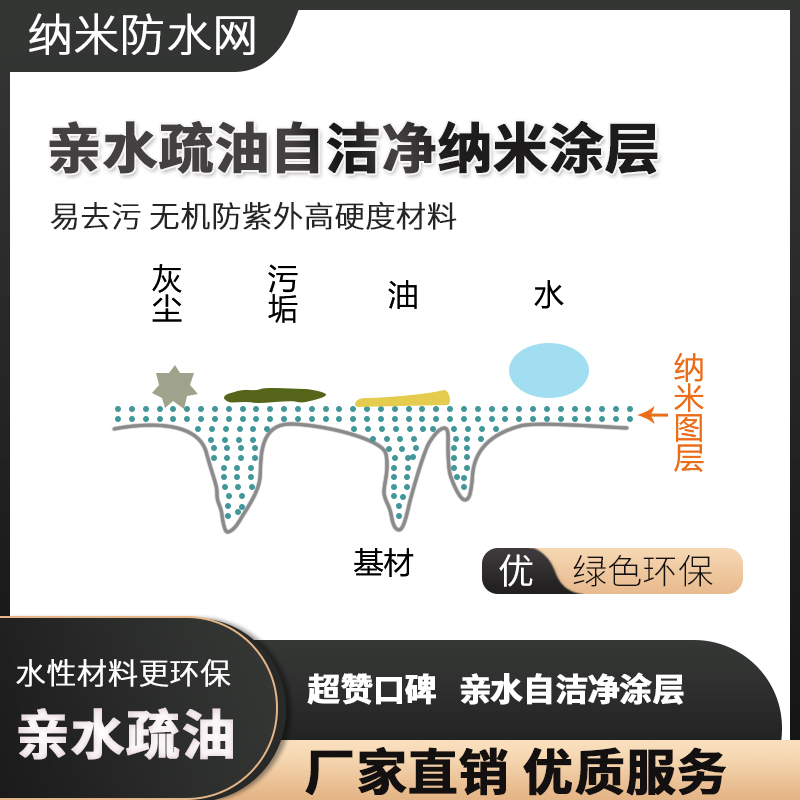

亲水疏油自洁净纳米涂层 易去污 无机防紫外高硬度材料

亲水疏油自洁净纳米涂层 易去污 无机防紫外高硬度材料

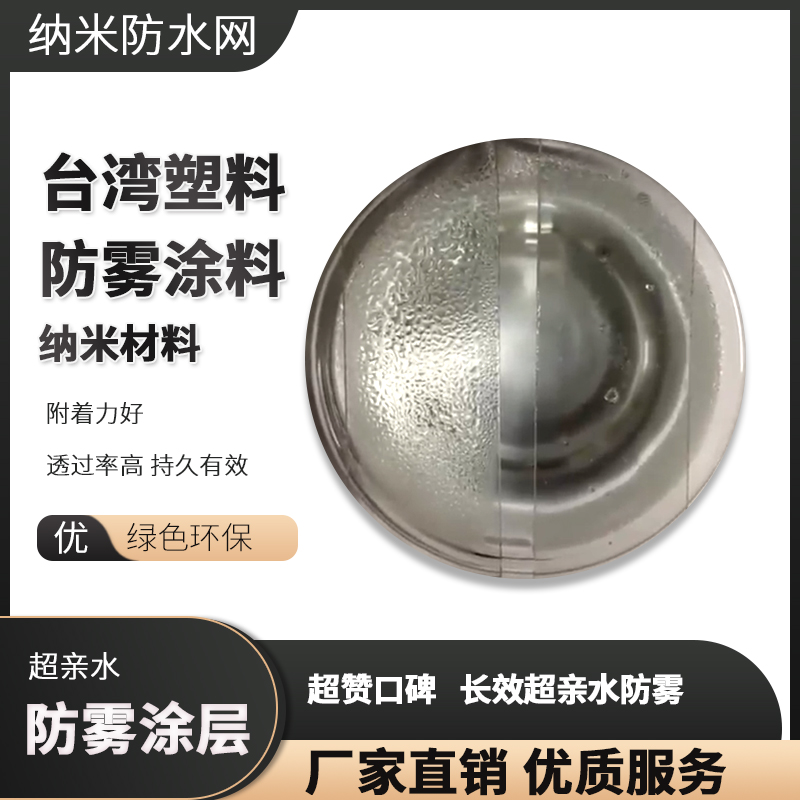

台湾超亲水防雾塑料专用 附着力好 透过率高 持久有效

台湾超亲水防雾塑料专用 附着力好 透过率高 持久有效