派瑞林用于LED的讨论

发光二极管(LED)的普及正在迅速增长,这主要归功于其适应性,能效和长期性能的益处。LED产品通常被置于各种恶劣条件下,包括灰尘的静电吸引力,潮湿或腐蚀性环境,化学或气体污染以及许多其他可能性。PCT与客户合作,确保LED获得最佳的保形涂层保护。电子广告牌,记分牌和交通信号等产品可以从无压力,真正保形的Parylenecoatings中获益。

Parylene的主要用途是保护产品免受降解。许多LED面临的极端温度,高湿度和长时间的紫外线照射与Para-CoatTechnologies Parylene涂层完全不相匹配。除了出色的水分和介电阻隔性能外,PCT Parylene涂层还具有超薄,通常为微米级的厚度,因此在考虑许多LED显示屏的总重量时,它们对LED组件的质量增加最小,这是一个重要因素。此外,Parylene涂层是光学透明,确保LED发光并持续很长时间。

Parylene对LED保护的好处:

· 优异的介电强度

· 超薄,重量轻,无针孔

· 耐极端温度

· 卓越的化学屏障和防潮保护

· 紫外线稳定性

LED涂层应用包括:

· 航空照明

· 商用制冷

· 电子广告牌

· 船用照明

· 户外照明

· 记分牌

· 视频显示

· 交通信号

· 车辆照明

The popularity of light emitting diodes (LEDs) is rapidlygrowing largely due to its benefits of adaptability, energy efficiency, andlong-term performance. LED products are often placed in various harshconditions that can include the electrostatic attraction of dust, humid orcorrosive environments, chemical or gaseous contamination and many otherpossibilities. PCT works with customers to make sure LEDs are getting the bestconformal coating protection. Products like electronic billboards, scoreboards andtraffic signals can greatly benefit from stress-free, truly conformal Parylenecoatings.

Parylene’s primary purpose for LEDs is to protect theproduct from degradation. Temperature extremes, high humidity and prolonged UVlight exposure that many LEDs face are simply no match for Para-CoatTechnologies Parylene coatings. In addition to their outstanding moisture anddielectric barrier properties, PCT Parylene coatings are ultra-thin, usuallymicron-range thickness, so they add minimal mass to LED components which is animportant factor when considering the overall weight of many LED displays.Furthermore, Parylene coatings are optically clear, ensuring that LEDs shinebright and will last an extremely long time.

Parylene Benefits for LED Protection:

· Excellent dielectric strength

· Ultra-thin, light-weight and pinhole free

· Resistance to temperature extremes

· Exceptional chemical barrier and moisture protection

· UV stability

LED coating applications include:

· Aviation lighting

· Commercial refrigeration

· Electronic billboards

· Marine lighting

· Outdoor illumination

· Scoreboards

· Video displays

· Traffic signals

· Vehicle lighting

随着电子产品防水需求的不断提高,从原先的 IP54到现在的IP67IP68等级!市场上出现了防水透气膜和防水透音膜,目前这两种不同的材料应用被搞混了,今天便与大家一起讨论防水透气

最近各地降雨量激增,所以手机就难免会沾点水,作为生活中不可或缺的电子产品,防水已经成为一个十分重要重要功能,而且个人对目前的IP68手机市场是相当不满意的。为什么?太贵

自然界中荷叶具有出淤泥而不染的典型不沾水特性(学术上称为Cassie-Baxter状态),具有自清洁、抗结冰、减阻、抗腐蚀等广泛应用价值,而玫瑰花瓣则具有水滴高粘附特性(称为Wenze

派瑞林各种粉材真空镀膜技术加工 纳米涂层防水处理

派瑞林各种粉材真空镀膜技术加工 纳米涂层防水处理

高阻隔强绝缘防汗液涂层蓝牙耳机3C电子产品IPX7纳米材料

高阻隔强绝缘防汗液涂层蓝牙耳机3C电子产品IPX7纳米材料

耐磨超疏水纳米材料 绝缘子架空导线电缆桥梁防覆冰涂层

耐磨超疏水纳米材料 绝缘子架空导线电缆桥梁防覆冰涂层

真空等离子气相沉积技术纳米防水镀膜加工 产能5万片天

真空等离子气相沉积技术纳米防水镀膜加工 产能5万片天

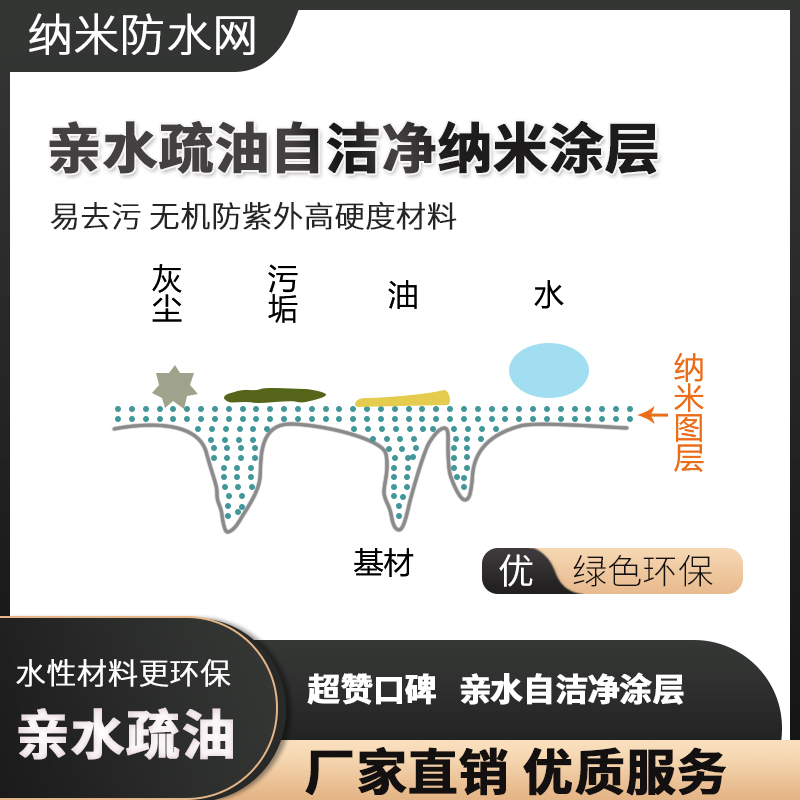

亲水疏油自洁净纳米涂层 易去污 无机防紫外高硬度材料

亲水疏油自洁净纳米涂层 易去污 无机防紫外高硬度材料

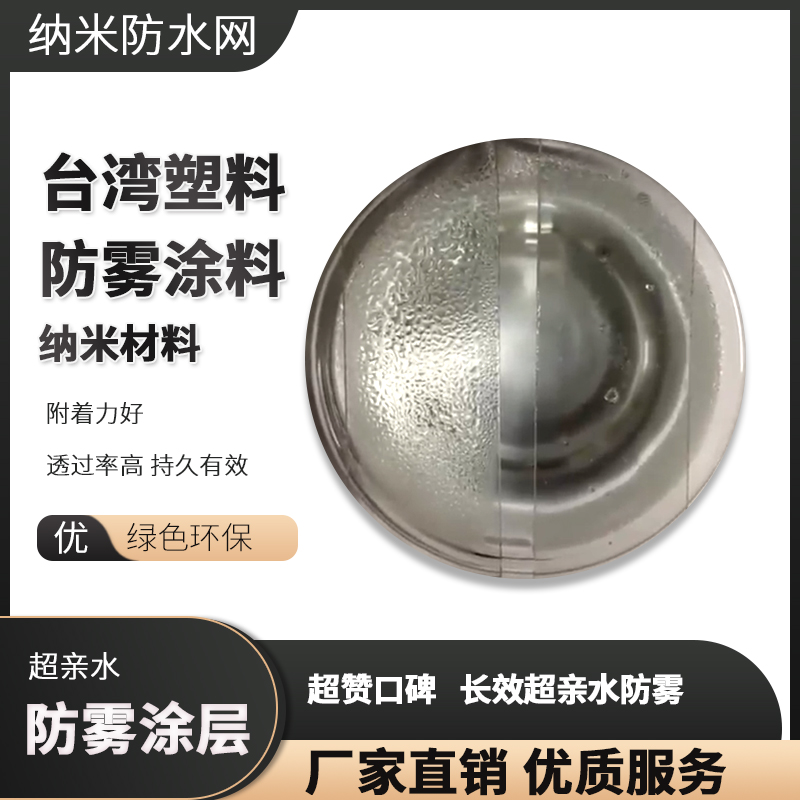

台湾超亲水防雾塑料专用 附着力好 透过率高 持久有效

台湾超亲水防雾塑料专用 附着力好 透过率高 持久有效